An auto-fusing finger extension that can be applied on the popular Turtlebrace wrist or the Harebrace wrist.

Its unique design permits the immobilization for:

– Boxer fracture

– Ulnar fracture

– Palmar support

– Dorsal support

The great flexibility of the components stabilizes the fingers more easily and with more precision than a traditional brace or cast.

It can be reshaped many times, without losing its qualities, allowing adjustment according to morphological changes or a specific protocol.

CHARACTERISTICS

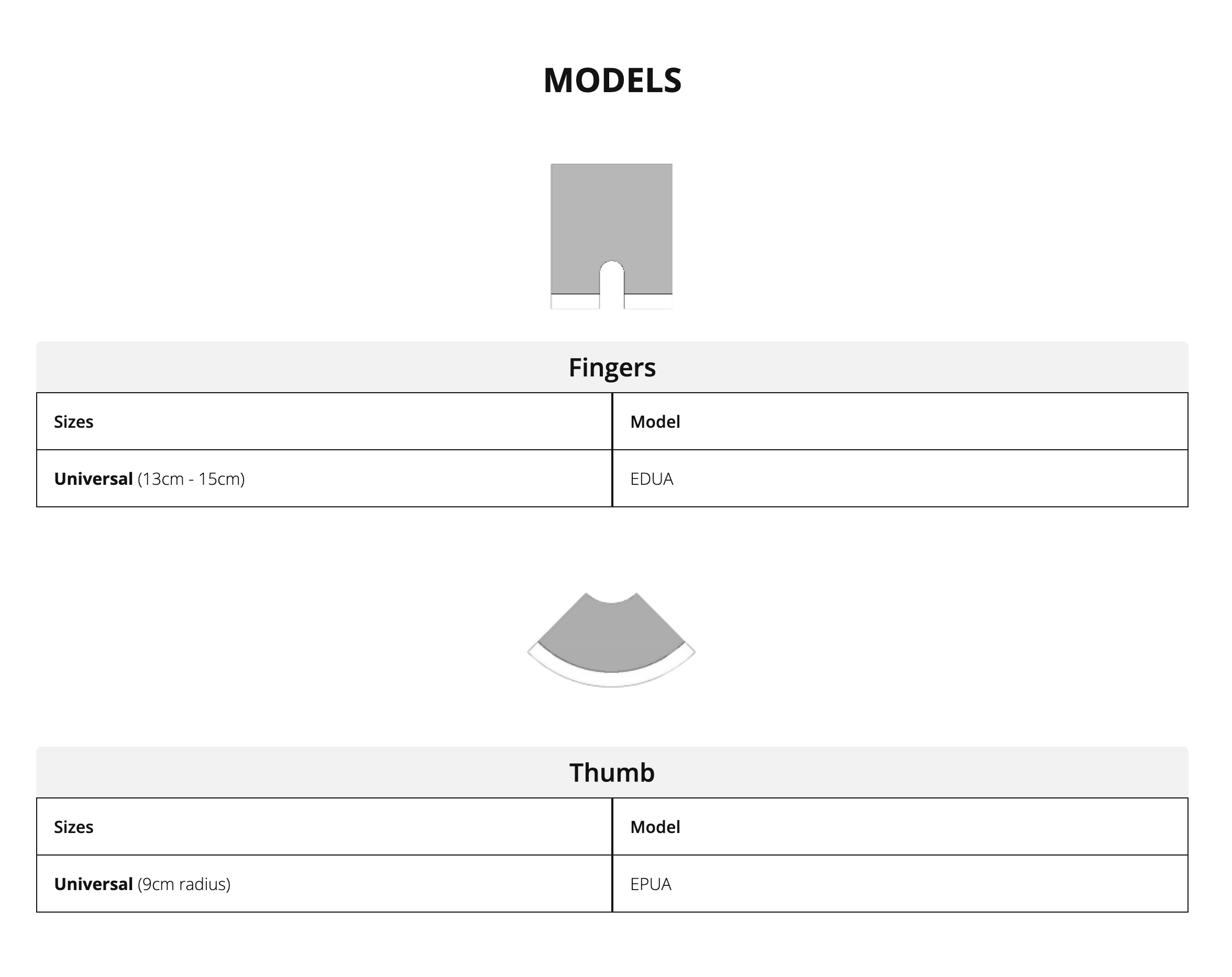

- Universal size.

- Direct molding on the fingers.

- Auto sticking and permanent fusion to the wrist brace (Turtlebrace or Harebrace).

- Can be cut to fit your needs.

- Antibacterial fabric

- Radio-transparent

- Submersible and auto-draining

- Re-moldable without limits nor degradation

- 3.2 mm thickness

- Compostable eco-friendly plastic

THREE SIMPLE STEPS

- Heat the brace in an oven between 67 °C and 85 °C (152°F and 185°F), or in the Turtlebrace heating bag until it becomes soft and elastic.

Do not use water or water vapor to heat the piece. Moisture will affect the fusion to the brace. - Once the piece has become soft and elastic, you can place the piece according to the need:

Boxer fracture

Slide the piece in between the 3rd and 4th fingers

Press the bare plastic on a dry brace, to fuse the piece to the brace.

Stretch to piece to cover the 4th and 5th fingers

Cut the excess material and place the fingers in the proper position.

Ulnar fracture

Slide the piece in between the 3rd and 4th fingers

Press the bare plastic on a dry brace, to fuse the piece to the brace.

Stretch to piece to cover the 2th and 3th fingers

Cut the excess material and place the fingers in the proper position.

Palmar fracture

Press a corner bare plastic to one side of a dry brace.

Stretch to piece to cover the sides and the bottom of all fingers.

Press the bear plastic on the dry brace, to fuse the piece to the brace

cut the excess material and place the fingers in the proper position. - When your patient’s fingers are in the desired position, wait for the piece to harden.

INDICATIONS

- Make sure that the temperature of the piece is not too hot for comfort or at risk of burning your patient before draping.

- The bare plastic can feel hotter than the rest, be careful not to burn your patient.

- Do not heat the piece over 100°C (210°F), because the fabric could burn or melt.

- Moisture will affect the fusion efficiency. Make sure the surfaces that are going to be fused together are dry and clean.

- If you use a heat gun, be careful not to burn the fabric.

Reviews

There are no reviews yet.